- +91-9886186643

- airchcoils@gmail.com

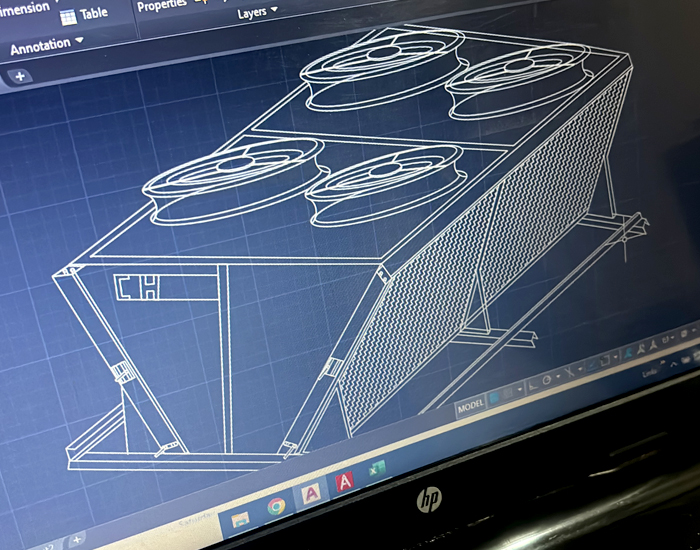

Design and Modelling

CH COILS INCORPORATION

Design and Modelling of HVAC Coils at CH COILS

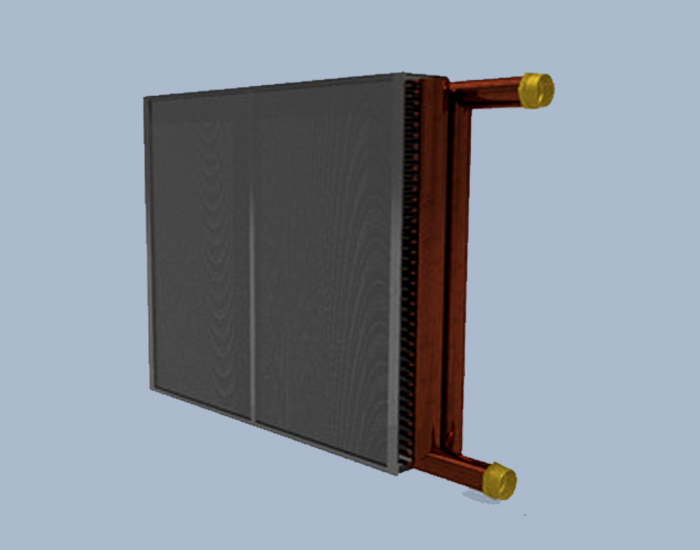

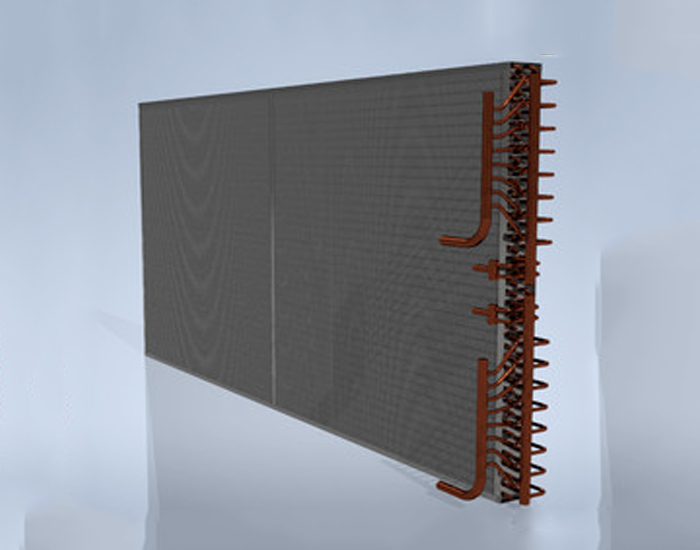

At CH COILS, we specialize in the design, engineering, and manufacturing of high-performance HVAC coils tailored for various applications, including heating, cooling, dehumidification, and air handling systems. Our advanced design process ensures that each coil meets optimal efficiency, durability, and energy performance standards.

1. HVAC Coil Design Process

Step 1: Understanding Customer Requirements

Identify the application type (Heating, Cooling, Dehumidification, or Refrigeration).

Define operating conditions such as airflow rate, temperature, humidity, and pressure drop.

Select suitable refrigerant or fluid type (Chilled Water, Hot Water, Steam, or DX Refrigerants).

Ensure compliance with ASHRAE, AHRI, and industry standards.

Step 2: Coil Configuration & Material Selection

Tube Material & Size:

Copper (standard) or stainless steel for corrosion resistance.

Available in 3/8", 1/2”, diameters based on heat transfer needs.

Fin Material & Type:

Aluminium (standard), copper, or coated fins for enhanced durability.

Coil Circuiting:

Standard and custom circuiting to match fluid dynamics and refrigerant properties.

Step 3: Coil Performance using Selection software.

Advanced Selection Software Analysis:

Selection Software Coil performance verification based on ASHRAE Proceed for the production process,

2. Types of HVAC Coils Designed at CH COILS

Advanced Selection Software Analysis:

Chilled Water Coils – Used in AHUs, FCUs, and cooling applications.

Hot Water Coils – Designed for HVAC heating systems.

DX (Direct Expansion) Coils – Essential for air conditioning and refrigeration.

Evaporator Coils – Critical for refrigeration & dehumidification.

Condenser Coils – Removes heat in air-cooled and water-cooled systems.

3. Key Benefits of CH COILS HVAC Coil Design & Modelling

Advanced Selection Software Analysis:

Optimized Performance – Engineered for maximum heat transfer and minimal energy consumption.

Customizable Designs – Tailored coil configurations for any HVAC system.

Durability & Longevity – Corrosion-resistant materials and coatings extend coil life.

Precision Manufacturing – Tight quality control and testing ensure reliable performance.

Industry Compliance – Designed to meet ASHRAE, AHRI, and ISO standards.

At CH COILS, we offer custom-engineered HVAC coils designed with precision and modelled for peak performance.